| Home > Who's Who > Companies > Parallel Kinematic Machines > Fatronik |

Company Profile of Fatronik |

|

The following information is courtesy of Mr. Agustín J. Sáenz (Fatronik). The CompanyFatronik is a private industry, created in 1986 and based in Spain, providing engineering services to a group of machine-tool manufacturers that in 1998 achieved sales for 200 million euros. During the last ten years, Fatronik has been improving existing products and devising new solutions for its shareholders, all of which SMEs, as well as creating new designs with innovative final results that comply with market demands. With 50 employees and more than 35 engineers, Fatronik is involved in the following activities:

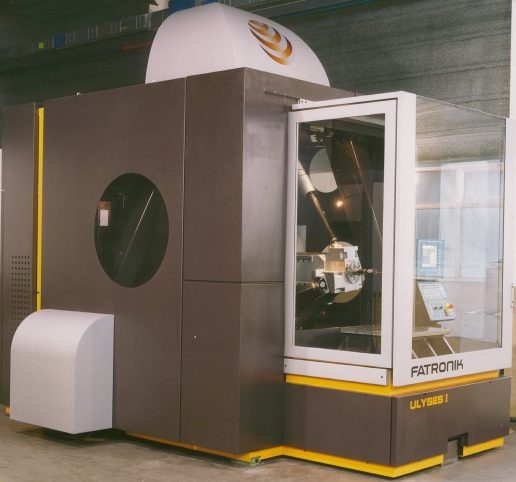

Fatronik has been working since two years on the application of advanced structures and kinematics to machinery. The company works on the commercialization of machines with this kind of new solutions in milling machines and automated assemblies (for the aeronautic sector), agile modules (for the automotive sector), and high speed machines (for moulds and dies). Fatronik is the coordinator of two important PKM projects: MACH21 and AHEAD. The MACH21 project involves twelve partners (LIRMM, WZL, ISW, INA, COMAU and others) from five European countries. Related Products and PrototypesThe only parallel kinematic machine of Fatronik that is currently commercially available is the 3-axis milling machine Ulyses. The system represents a new standard in machine tool construction. It is a parallel kinematic machine tool, with a brand new structure, allowing Fatronik to obtain an European patent (EP 1 027 965 A1). The machine has been entirely developed by Fatronik.

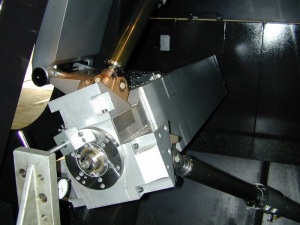

Ulyses is a 3-axis translational PKM. The mechanism is driven by three prismatic actuators in a typical tripod connection. The novelty is the use of planar scissors-like constraining chain. With the achieved dynamic performance and market price, Ulyses is claimed to excel similar PKMs such as Heckert's SKM 400 and RWTH Aachen's Dyna-M. Below are some of Ulyses' characteristics:

Fatronik is currently designing a new version of Ulyses, dubted Ulyses ZAB. The new 3-axis machine tool is similar to Neos Robotics' Tricept. However, the same constraint as in the Tricept is provided in a reversed order, i.e., translation (the linear guide) followed by two rotations (the Hooke joint). This eliminates the large swaying motion of the heavy constraining strut and improves dynamic performance at the cost of a narrower workspace.

Fatronik works also on an original 3-axis machine tool, named Hermes. The PKM's mobile platform has one pure translation with fixed direction and two rotations. The aimed application is the automation for the assembly (machining and riveting) of aircraft structures. However, the example of the similar Z3 Head by DS Technology, which is a 3-PRS parallel mechanism, may suggest the alternative use of Hermes as a spindle head.

|

|

Home |

Bibliography |

Patents |

Terminology |

Reviews |

Software |

Who's Who |

News Site Map | Site Search | Contact Us | About Us |

| Copyright © 2000–2001 by Ilian Bonev | Last Update: October 7, 2001 |