The Parallel Mechanisms Information Center

(

http://www.parallemic.org)

|

ParalleMIC The Parallel Mechanisms Information Center ( http://www.parallemic.org) |

|

The basic idea of haptic devices is to provide users with a force feedback information on the motion and/or force that they generate. Haptic devices are useful for tasks where visual information is not sufficient and may induce unacceptable manipulation errors, for example surgery or teleoperation in radioactive/chemical environments. The aim of haptic devices is to provide the user with a feeling of the situation. In this article we will try to review a particular type of haptic devices, namely those based on parallel mechanisms.

Recent haptic devices are becoming more and more sophisticated and include several innovative features. To give the user a precise feeling of the end-effector slave manipulator situation, the haptic device should be able to generate a wide range of dynamic behavior. As proposed by Millman and Colgate*, some important features for high-performance haptic devices should be highlighted: low inertia, high stiffness, low friction, backdriveability, near-zero backlash, gravitationnal counterbalancing, sizeable workspace, multiple degrees-of-freedom, and human matched force capabilities. In addition, compactness is highly desirable. It can be seen that parallel mechanisms are appropriate candidates for haptic devices since they are well-known for their high stiffness and low inertia, which enables large bandwidth transmission of forces. Other desired properties can be achieved through suitable mechanical design and proper control scheme. A particular stress must be put on the transparency of the device regarding the user; the haptic device must not distort the reflected forces/torques by its mechanical characteristics.

In this article, we present a brief overview of the most representative haptic devices based on parallel mechanisms. However, many existent desings have been omitted for reasons of lacking or redundant information. If you consider that we are missing something important, feel free to contact us to provide us with adequate information. Items referred in the bibliography are indicated by a "*" sign. Links to related web sites can be found either directly in the text as hyperlinks, or at the end of the present article.

It is difficult to control parallel mechanisms in real-time, as required with haptics, because the forward kinematics is highly nonlinear and is often not in closed form. Moreover, the gravitationnal counterbalancing required for the hand controller to appear transparent to the user, leads to software-operated static balancing, which is increasing the complexity and the time consumption of the control scheme. To overcome these difficulties, fast hardware capabilities are required. Alternatively, extra sensors can be used. Because of the increasing power (computing frequency) of commercially available computers, controlling a parallel mechanism with efficient refresh rates can now be achieved.

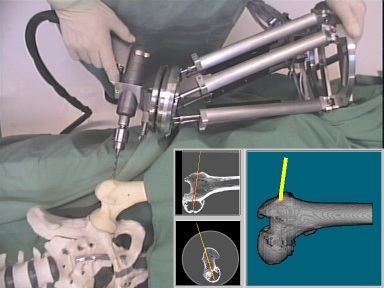

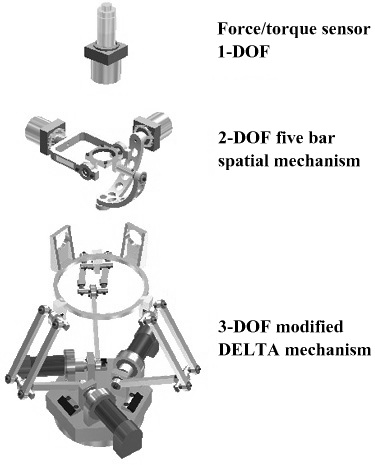

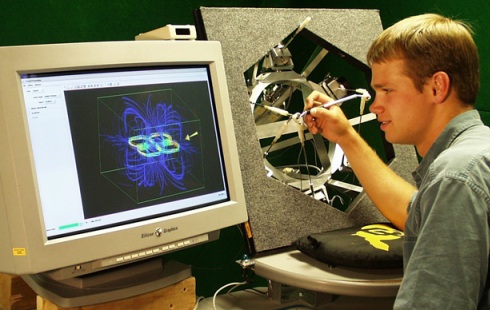

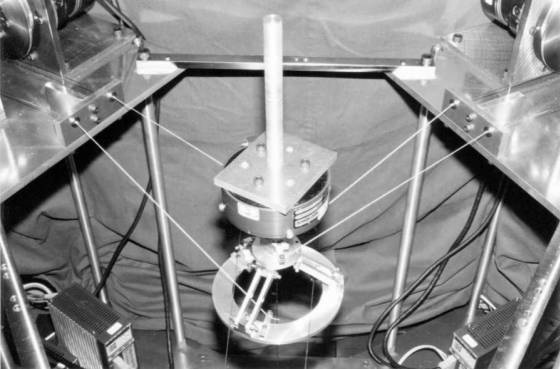

Medical robotics is of course, an aera of predilection for high-performance haptic devices. They can provide the surgeon with tremor-free movements by down-scaling the force applied, and the physical therapist with reliable rehabilitation system. An European project, the CRIGOS robot, an acronym standing for Compact Robot for Image Guided Orthopedic Surgery, is basically a Gough-Stewart platform aimed at providing the surgeon with a high-performance tool for bone surgery that is both a manipulator and a haptic device. Gough-Stewart platforms are also used by the CAIP in Rutgers University to create an ankle rehablitation system for domestic use. Besides medical applications, the Gough-Stewart platform has also been successfully marketed by AEA Technology as the bilateral platform to control nuclear robots, and the University of Colorado as a general Haptic Interface for large multi-dimensional volumes of data.

![]() Testing the CRIGOS Robot

Testing the CRIGOS Robot

(courtesy of K. Radermacher and G. Rau, Helmholtz-Institut Aachen, Germany)

Another possible design involves spherical mechanisms. They present the particularity of having a fixed center point that can be chosen at the center of the user hand, thus, eliminating the need for arm motion. Moreover, particular designs can provide unlimited rotation around this central point, allowing very large workspace, limited only by the low-scaled dexterity and mechanical interferences. Such a device has been successfully tested at Laval University, named the SHaDe*.

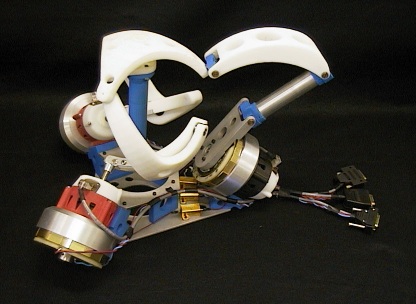

![]() The 3-DOF Spherical Haptic Device, SHaDe

The 3-DOF Spherical Haptic Device, SHaDe

(courtesy of Prof. Gosselin, Laval University, Canada)

The latter is a 3-DOF spherical mechanism and has an optimized workspace with a very high average dexterity and a non-null minimal dexterity, i.e., no singular configurations at all. A spherical mechanism has also been used by the Space Machines Laboratory* at Tohoku University as a complementary subsystem of a modified Delta positionning mechanism, leading to a hybrid design with high performance: large workspace, low inertia, and compactness.

![]() The SML Haptic Device (courtesy of Prof. Uchiyama and Prof. Tsumaki)

The SML Haptic Device (courtesy of Prof. Uchiyama and Prof. Tsumaki)

The Delta from EPFL can be used as an haptic interface by itself, as the one commercialized by Force Dimension. A new 6-DOF version has just been released on the market. An ideal mechanism would have constant performances all over its workspace, a property known as isotropy. Unfortunately, typical mechanisms do not present this asset. Nevertheless, an optimized design based on the maximization of criteria such as the dexterity can improve the overall behaviour of the system in a dramatic way. The useable workspace must be, as usual, free of singular configurations, leading once more to a careful analysis and optimization of the design. An interesting method to obtain a singular-free workspace can be achieved by actuator redundancy as used by Reboulet* at ONERA/CERT, and Buttolo at Washington University.

Other designs for the legs of the platform can be used, instead of previously described systems. The Haptic Master of Dr. Iwata Lab is a haptic device for desktop use (fingertip manipulation) based on three pantograph legs, particular emphasis has been put on reducing the inertia of the system, leading to a high-bandwidth device. Pantograph designs can also be used for small and reduced DOF haptic devices, as proposed by McGill University as a device for visually handicaped people. The Robotics Lab at KAIST uses three five-bars linkages in lieu of classical prismatic links to create their hand controller. A linear haptic device with reduced DOFs and linear motors is also investigated in the Mechatronics and Control Lab at Korea University. Recently, a 6-DOF parallel haptic device has been designed at Hanyang University.

![]() Colorado University Haptic Device

Colorado University Haptic Device

(courtesy of Prof. Pao, Colorado University, USA)

Cable mechanisms present interesting advantages in comparison with conventional parallel mechanisms: their workspaces are usually much larger and due to the lightweight of cables inertias are almost null. Hence, fast motions can be achieved through a wired system. However, two main drawbacks have considerably slowed the expansion of the use of wired mechanisms. First, cables can only produce forces in one direction complicating the analysis of the usable workspace, and second, the latter unidirectional constraint implies that in order to fully control the mechanism, actuator redundancy must be employed. Nevertheless, during the last few years, those difficulties have been overcome and successful systems have been created such as Falcon, Skycam or Charlotte robots.

For a haptic device, a very interesting architecture has been created in the PERCRO Lab consisting of a 6-DOF platform with cables/tendons transmission. What makes this design particularly original is that it has been extremely well studied using actuator redundancy, kinematic optimization, and maximized controllable workspace. Again in Italy, the LAR-DEIS laboratory in Bologna proposed a finger-operated haptic device, the Visual Decoder by Touch (VIDET), with 3-DOFs, completed by a visual acquisition system and carried as a backpack. Tokyo University has developped a Spatial In-Parallel Wire-Driven Mechanism with 6-DOFs using only 7 wires with high force transmissibility and large practical workspace.

![]() Tokyo University Wire Haptic Interface

Tokyo University Wire Haptic Interface

(courtesy of Prof. Takeda, Tokyo Institute of Technology, Japan)

The BioRobotics Lab of Washington University proposed a wide range of simple linear haptic devices with steel cable transmission. Despite the large inertia due to the mechanical design and heavy moving masses, they keep as a main advantage, a very large workspace.

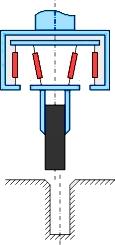

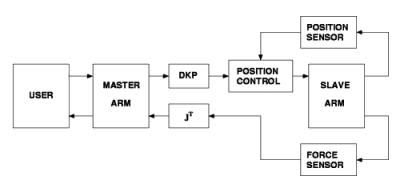

It was in the late 40's that Raymond C. Goertz* working with the Argonne National Laboratory of the U.S. Atomic Energy Commission, invented the first master-slave manipulator. Publicly demonstrated in 1949, it was intended to manipulate radioactive substances. This manipulator was based on a serial architecture but yet, the haptic sensation was transmitted to the master arm through parallel mechanism linkages. Later, in the 50's, Goertz was again the first to implement force reflection for manipulators using servo-motor systems. Medical applications followed soon in the next decade when Rotschild and Mann developed a force-feedback artificial elbow for amputees. But, until recently, the computing power of electronic systems was too small, or shall we say "too slow", to carry on the calculations in a safe manner, causing these systems to become unstable. To overcome this problem Daniel E. Whitney* presented in 1978 the Remote Compliant Center or RCC — a mechanical system based on a parallel architecture to provide fast and reliable assembly with passive compliance.

![]() The Remote Compliant Center and a Master-Slave Manipulator Control Scheme

The Remote Compliant Center and a Master-Slave Manipulator Control Scheme

Active compliance or impedance control was then presented by Neville Hogan* in a concise and rigorous approach in 1985, to provide more flexibility for assembly robots. The basic idea is to elaborate a control law that gives the end-effector a certain impedance (usually mass-spring-damper) by proper command on the actuators. Credits for impedance control should however be shared with R. Paul, B. Shimano, and J.K. Salisbury. In the past two decades, research on force control has grown in an exponential fashion with two main streams of applications. Firstly, there is the affordable way to enhance robotic system abilities by giving them a supplementary sense, the sense of touch. And secondly, there is the possibility to provide users with the same feeling using a mechanical device, then called a haptic device. Researches about force control are still very active to provide fast and reliable algorithms. Readers willing to study that subject in detail may found an interesting summary in the recent book Robot Force Control* from Bruno Siciliano and Luigi Villani.

. . .

Parallel mechanisms have shown their accuracy with many successful applications throughout the world as haptic devices. Their stiffness and low inertia make them appropriate to this end. Since haptic systems are used by a human operator who has a limited range of movements, the disadvantage of small workspace of parallel mechanisms is no longer essential. The Moore evolution of computer systems has now almost overcome the last drawback of parallel mechanisms — their complicated input-ouput relationships, and hence, their computationally intensive control. Many different designs have produced successful systems and impressive capabilities in comparison with classical haptic devices such as the well-known Phantom™ manufactured by SensAble Technology and shall certainly continue their expansion through the market.

| Copyright © 2000– by Ilian Bonev and Lionel Birglen | Last Update: September 3, 2001 |